The container is then straight away filled Along with the liquid or semi-stable substance in exactly the ideal amount.

Kram provides there are two Key strategies to continue to keep the item amazing though applying BFS technology. “The first does the most get the job done, retaining the solution in a small temperature (e.

What arrives out is a fully sterile completed item. It’s an excellent presentation For a lot of medicine, which include biopharmaceuticals. Sterility is vital for biologics and all kinds of other medicines because it helps prevent microbial contaminants in products and solutions.

Because the parison, a soft but sturdy precursor to the final plastic containers, descends, it can be fulfilled via the precision from the BFS device's mould. This mold encases the parison, shaping it into your destined container variety.

The standard and Traditionally most popular sealing solutions – and the issues connected with them

“In assistance” repairs are achievable with no fret of no matter whether spare elements can be obtained as many updates and repairs can be achieved without the have to have to purchase new products.

BFS manufacturing is anticipated to knowledge an yearly growth fee of 8% concerning 2019 and 2029. The expansion are going to be attributed to pharmaceutical corporations, in addition to other rising therapy marketplaces, for instance biologics, which have been conducting compatibility and stability screening with large molecule merchandise.

Gabrielsen states: "Together with the growing regulatory calls for, BFS technology stands out by considerably minimizing contamination threats, ensuring compliance with stringent sterility criteria."

Vaccines used to be distributed 10 doses for every vial plus the doctor's Place of work would attract out 1 container. There was a force to visit single-dose prefilled syringes—it lowers the physician earning that manipulation and several entries into one container,” he reported.

This aseptic liquid processing technology offers substantial strengths around traditional filling procedures, because it eliminates potential resources of contamination, for example ingredient washing and operator interventions.

We are actually offering substantial-top quality products to sufferers for approximately 30 many years. We're dedicated to continually Checking out strategies to enhance our amenities, our blow fill seal technology folks, and our procedures, with the final word purpose of assisting additional individuals.

As additional corporations integrate this process, They may be tasked Using the problem of sustaining rigid particulate and biological contamination controls. Despite the fact that this method eliminates the chance of human contamination, forming the container in-line with BFS results in a brand new source of particulates when the fabric is extruded and cut.

Filling: The open stop with the container is positioned under the filling station. The desired products, like a liquid or powder, is injected into your container via a filling nozzle. The filling approach is typically carried out in the managed and sterile environment to make certain product or service security.

We will only deliver the ideal here advice and Remedy if we realize your prerequisites. We have been Outfitted to manage all the things from BFS packaging and machines to agreement manufacturing and progress to comprehensive-scale BFS output. We eagerly await your obstacle!

Edward Furlong Then & Now!

Edward Furlong Then & Now! Haley Joel Osment Then & Now!

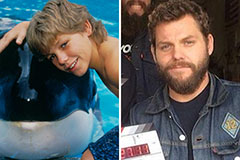

Haley Joel Osment Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now!